STRENGTH IN SERVICE

We can produce thousands of standard shapes, plus custom extrusion design, tooling and finishing to meet the most demanding needs. Our custom tooling capabilities, technology, and state of the art powder coating facilities are all here to help meet and exceed your expectations.

EXTRUSION PRESS CAPABILITIES

A diverse range of solid, hollow and semi-hollow shapes are extruded daily at Flextrude. We have two Watson Stillman presses and one Lake Erie press, all of which handle up to to 8” diameter billet in lengths up to 32″ and enable us to produce up to 10” inch wide extrusions. We use primary billet in 6063 and 6005a alloys with standard tempers of T4, T52, T5, and T6.

Given the nature of our equipment and efficiency of our die changes, we can offer production runs as low as 1,000 pounds. This positions Flextrude as the ideal choice for prototype work or small volume runs. Our equipment is also capable of high production volume as well, with an annual capacity in excess of 45,000,000 pounds.

Pounds Annual Capacity

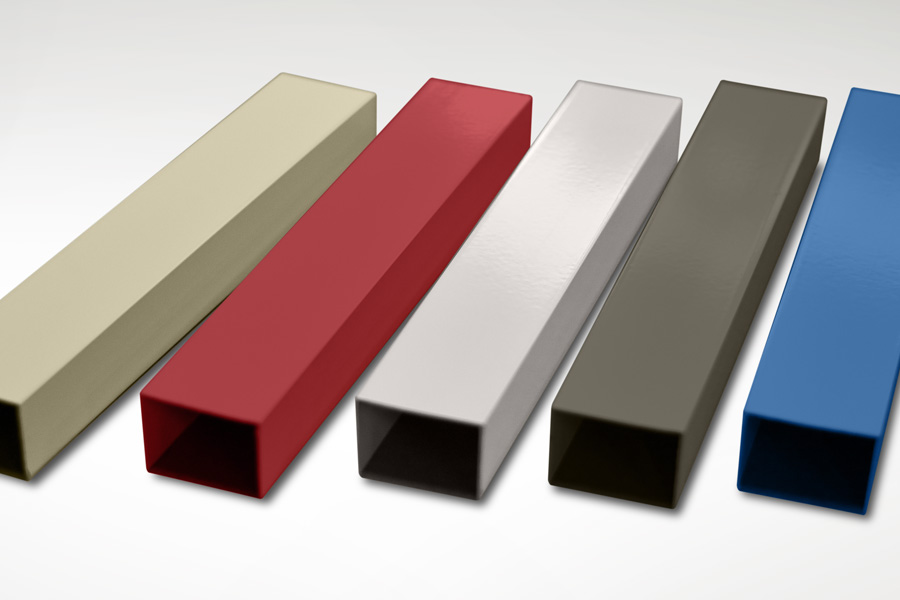

PAINT LINE & FINISHING SERVICES

Superior quality is our single-minded purpose behind the paint finish that we provide. Our state-of-the-art horizontal certified powder coating line is capable of applying paint on lengths up to 40 feet.

CUSTOM EXTRUSIONS

While we offer an extensive line of standard aluminum extrusions, our team can also work with you on custom projects to suit specific applications. This process starts with discussing design and ultimate application of the final product so we can work through specifics of die, grade, final shape, coating needs and delivery timing. If your job requires a conversation about our custom services, let us know how we can help.

ON TIME. EVERY TIME.

In order for you to deliver, it’s critical that we strive to deliver on time, every time. Our team values that delivery as an important phase of production. This is why we are committed to delivering orders “right the first time, on time, every time.” To provide this dependable service, we maintain our own delivery fleet. We understand that our customers’ production deadlines are important and that our reputation is built on providing the most competitive lead-times the industry has to offer. We work with our customers to provide “Just-In-Time” delivery solutions to streamline production, reduce inventory costs and improve lead times.

CUTTING, PACKING AND SHIPPING

Finish cutting is available to cut the profile to any specified commercial length from two inches to 40 feet with precision tolerance.

Packaging services are available to ensure your extrusions arrive undamaged and ready to be manufactured into your final products.

Having our own delivery fleet allows us to maintain control of shipping costs and timing to consistently meet customer needs.